Author: Philip Holgersson (Head of Product) - philip.holgersson@ynvisible.com

Ynvisible’s printed E-Paper displays enable a new range of battery-less products. Why? Ynvisible’s E-Paper displays are extremely low power. Low enough to harvest energy from wireless communication interfaces such as NFC. In this article, we’ll provide a practical implementation guide on how NFC can be used to power Ynvisible’s E-Paper displays.

Quick Facts About Ynvisible's E-Paper Displays

As already mentioned, Ynvisible's printed e-paper displays are ultra-low power. The recommended driving voltage is ±1.5V and one square centimeter active display area requires approximately 1 mJ to activate. This translates to roughly 1-2 µW/cm2 for an always-on display.

The displays also have an image memory (or image retention), which is an important parameter for battery-less applications. Ynvisible's standard displays have an image retention time of approximately 5 minutes to 15 minutes. After this period the contrast start to fade and, depending on the use case, a small refresh pulse is required to maintain full contrast.

The displays are manufactured using roll-to-roll screen-printing and lamination processes. They are non-toxic, ITO-free, and mainly comprised of PET plastic. The plastic substrate and roll-to-roll production means thin, flexible, scalable, and highly cost-effective displays. Get started using Ynvisible's e-paper display kit.

What is NFC?

NFC (an acronym for Near Field Communications) a communication protocol for short-distance data exchange between electronic devices. The communication is based on an inductive couple between two antennas. Compared to many other communication interfaces NFC does not need to have built-in power in one of the two communicating devices. Instead, power is harvested from the transmitted signal sent by the NFC reader/writer (such as a smartphone). The most common use-case for NFC is contactless payments.

What is required to power Ynvisible E-Paper display with NFC?

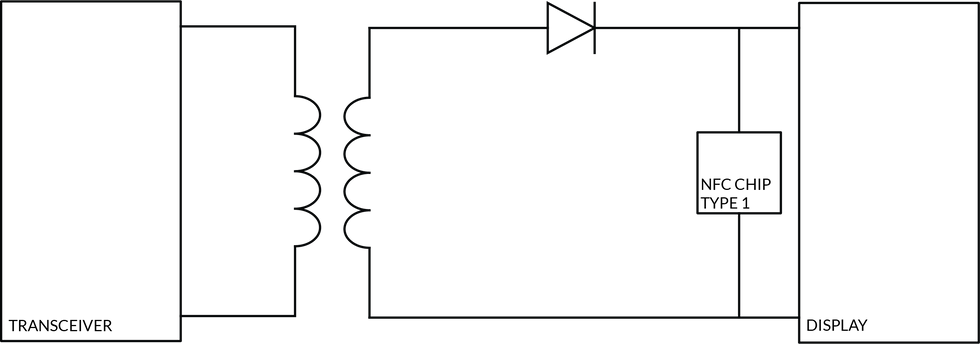

Fundamentally, an antenna and a diode to rectify the current is all that is required to drive the Ynvisible displays with an NFC signal. Inductive coupling between the transceiver and the antenna will transfer the power from the antenna to the display. The signal must be rectified with, for instance, a rectyfing diode since the display needs DC (direct current) to turn ON. The rectifying diode can be placed in parallel with the display if the display content is designed to fade out shortly after activation.

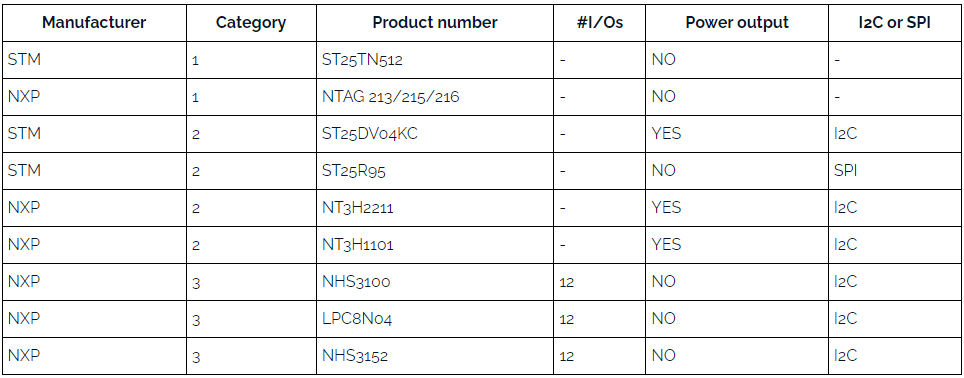

However, an NFC chip would be required if the application requires communication, such as reading an identification code (RFID) or writing data to the device. There are many different versions and manufacturers of these chips, and they have different capabilities. They can be divided into three distinct categories:

NFC data storage chips, the transceiver can read and/or write data to the chip.

NFC data storage ICs with I2C communication and power output (energy harvesting). These chips can be used to power and/or communicate with an MCU over NFC.

NFC chips with embedded processor. These chips can be seen as MCUs with NFC capability, meaning that they have typical MCU capabilities but with the possibility to be powered and/or communicated with through NFC.

Examples of these ICs are summarized in the table below:

Each IC category requires different implementations of the display. These different implementation methods are presented below:

APPROACH 1: CONNECT IN PARALLEL WITH NFC CHIP

In this case the display is connected in parallel with the NFC chip. There is no direct interaction between the IC and the display. Both the chip and the display are powered by the NFC signal. In this case, the display will be turned on, independent of the transmitted data.

APPROACH 2: POWER OUTPUT OF THE NFC CHIP

If the chip is of category 2 the display can be connected to the power output of the chip. As in approach 2 the display will be turned on, independent of the transmitted data.

APPROACH 3: MCU IN BETWEEN THE NFC CHIP AND THE DISPLAY

Another implementation with chip category 2 is to use a host controller (MCU) in between the chip and the MCU. This enables the MCU to read the data in the NFC chip in turn enabling conditional display driving. This could be useful when the display should be turned on, only if the user has the authority to read the label.

APPROACH 4: USE BUILT IN GPIOS TO CONTROL THE DISPLAY

Approach 4 is the same as approach 3 but since the MCU capabilities are built into the NFC chips of category 3, no in-between host controller is required.

Why NFC-Powered Displays?

NFC as a power source is replacing batteries. Batteries are typically limiting the adoption of electronics and printed intelligence in new applications from a cost, sustainability, and recyclability perspective. Ynvisible together with partners and clients are targeting markets including medical technology, smart packaging, smart cards, and brand protection and security devices.

The NFC+Display concept is a platform on which sensors and other printed electronics can be added to help shape the future of intelligent objects. Please do not hesitate to contact us if there are any questions. You should also check out our online store to get started.

Comentarios