This technology is required to simplify the manufacturing of microLEDs- this way one need not transfer R G B uLEDs but can only transfer the already efficient blue uLEDs and achieve RGB color via red and green QD color conversation.

There are of course multiple material challenges including achieving Cd-free RoHS-compliant green and red QDs with (1) high enough thermal and light stability for direct integration into microLED chips/dies, (2) high blue absorbance even at low thicknesses to prevent blue color leakage, (3) narrow FWHM and high QY, (4) low self excitation, etc

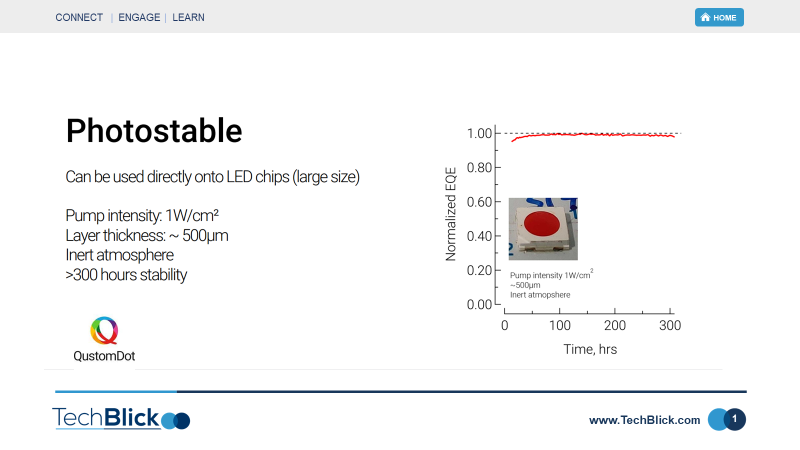

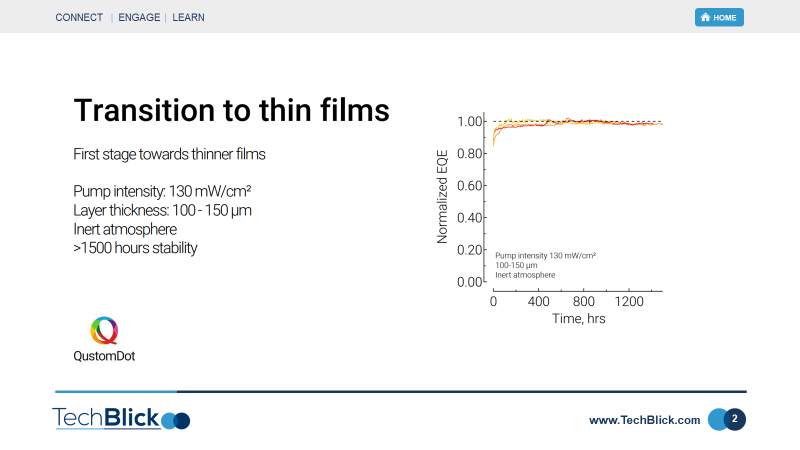

QustomDot -spin off from Zeger Hens group at Ghent University- is making excellent progress in this field. They have a novel high-controlled synthesis process for InP based QDs. Last year, at TechBlick they shared some interesting stability data for QD integration in macro and thin film LEDs. These results are shown in the slides below. They show a clear pathway towards development of QDs for direct on-uLED integration

The 500um thick QD level integrated on a macro LED shows >>300hours stability even under 1W/cm2, and a 100-150um QD thin film under 130mW/cm2 also shows >>1500 hours photostability in insert conditions

These are results from last year. To hear the latest developments from QustomDot on QD-on-microLED please join TechBlick's microLED and QD event. Check the world-class agenda at www.TechBlick.com/microLEDs

#microLED#miniLED#quantumdot#LED#displays#displaytechnology#RoHS#

Comments