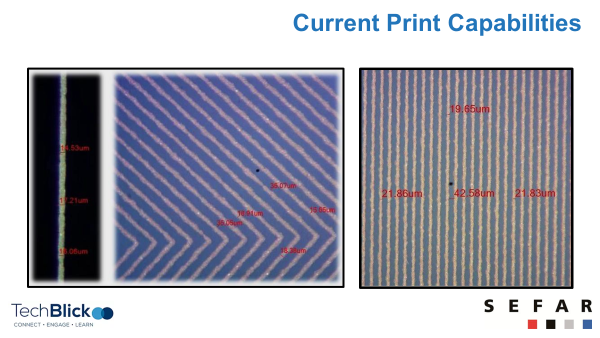

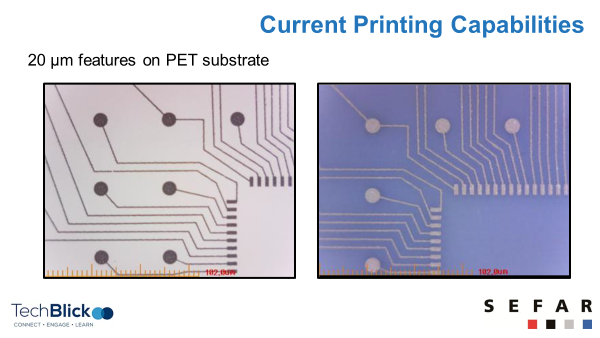

The progress of screen printing towards fine line printing has been incredible going from 100 µm features before 2010 to 70 µm to 2015 to 40 µm in 2018 and now pushing - in development- towards 20 µm and less. In parallel, the wet thickness of the printed line have gone down from 12um or so in 2018 to now just 4um.

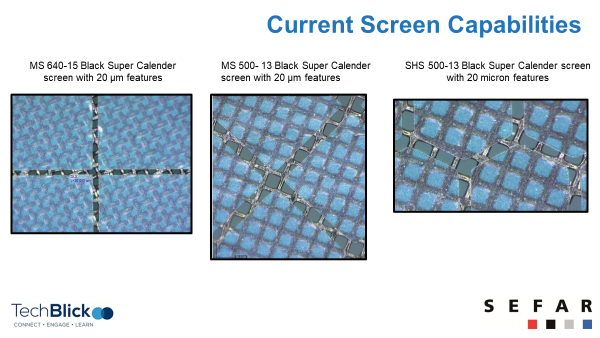

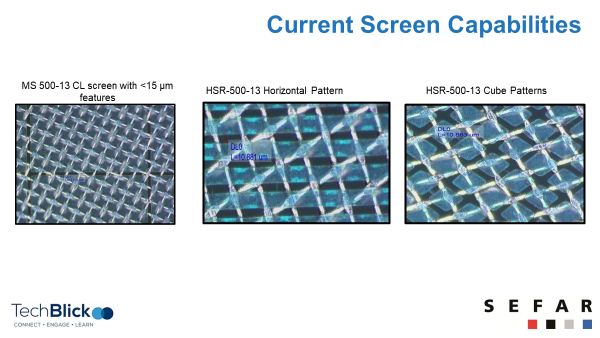

In the slides below, Jeffrey Campbell from Sefar Inc. shared examples of screens for fine line printing and showcases fine (<20um) printed features.

Advances in all elements of screen making technology have been crucial in driving this development forward. In his presentation at TechBlick Jeff also explained the key technological steps required in enabling and sustaining this trend. These include

1- fine mesh: this is a must as a finer mesh enables higher openings and thinner lines even at high mesh counts. This is shown below. In this slide, you can examples of printed features using 11um stainless steel meshes from Asada Mesh. Narrowing the diameter of the mesh may sound easy, but shaving each micron meter requires three years of intense development!!

2- mesh calendarig: flattening of mesh with rollers improves tensile strenght of the mesh and provides dimensional stability. This enables better control and print-to-print consistency even in fine feature printing

3- emulsion flatting: Reduces the surface roughness of the screen’s surface and reates a more consistent corridor for the paste to travel through. Furthermore, it improves the edge definition of the final print

In the slides below you can see many examples of various screens (mesh + emulsion + additional processing like calendering) suited to fineline printing (20um or less)

To learn more visit www.TechBlick.com

Comments