Hole-transporting layers (HTLs) are an essential part of an organic photovoltaic (OPV) device stack. Currently, printable HTLs do not typically offer compatibility with next-generation active layer materials such as PM6 and Y-series NFAs. The research team at Brilliant Matters has been working to address these and other issues. They have recently launched BM-HTL-1

BM-HTL-1 is a fully printable, high-work function hole-transporting layer (HTL) designed for use in organic optoelectronic devices such as solar cells or photodetectors. It is aimed at delivering good film properties, wettability, and processability while retaining favorable electronic properties for optoelectronic applications.

Designed for good compatibility with modern donor polymers having energetically deep HOMO levels, BM-HTL-1 can eliminate the need for evaporated hole transport layers in organic solar cells.

It is a printable organic alternative to MoOx and is more energetically suitable (deeper work function) than PEDOT: PSS for OPV applications. Technical features include :

•Ethanol-based formulation with low water content for printed electronics. •Energetically deep work function (5.5-5.6 eV), enables the use of deep HOMO level polymers and reduces the need for evaporated HTL layers such as MoOx during device prototyping. •Printable in thick layers (~200 nm) while maintaining function as an HTL (critical for large-scale OPV Printing)

•Conductivity (average): 0.4 S/Cm@200nm film

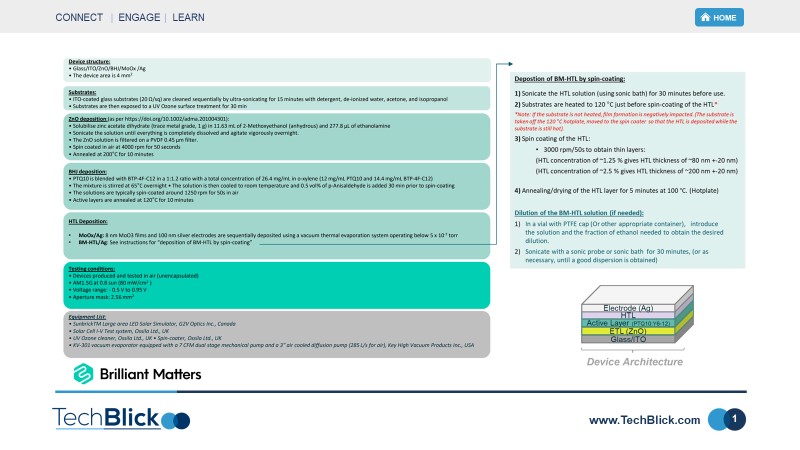

In slide 1 below you can see how one can prepare a device with PTQ10:Y6-12. Here, you can learn about device structure, substrate choice and processing, and the deposition procedecure for the ZnO layer, the BHJ and HTL layer as well as tsesting conditions. You can also learn about the required equipment set to acheive this. In this case, the BM-HTL is deposited by spin coating on a pre-yeated substrate followed by annealing/drying for 5min at 100C

In slide 2, you can see the device perforamnce, benchmarking the application of BM-HTL vs PEDOT:SS and MoOx hole transort layer. As it can be see, the FF matches that of MoOx whilst the PCE exceeds it! This is a great result

Slide 4 shows the results when the active channel material is changed from PTQ10:Y6-12 to PM6:Y6-12. Here again, the BM-HTL (spin coated) matches the performance of MoOx as the hole transport layer, offering almost identical FF (fill factor), Voc and PCE

To learn about this and other technology helping share the future of photovoltaics (organic PVs, perovskites, CIGS, and tandem PVs) see this agenda www.techblick.com/PV2022

Comments