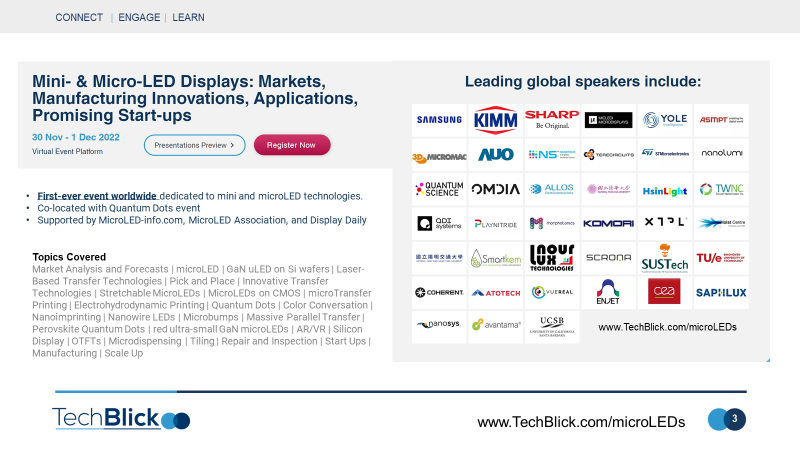

Manufacturing in particular mass transfer and repair remain the biggest challenges in realization of microLED displays. To simplify the process, many propose to transfer only the blue (or even a UV) LED and achieve RGB by depositing color converters such as quantum dots. This requires an additional deposition step. But what if one could achieve chip-scale monolithic integration of QDs and GaN microLED chips? Indeed, Saphlux proposes just this and will present this on 30Nov-1Dec 2022 at TechBlick's microLED and QD event www.TechBlick.com/microLEDs

Saphlux has taken this approach one step further. Instead of post-transfer deposition of QDs, their technology enables chip-scale integration of quantum dots and microLEDs. In this technique, a nano-porous structure is directly formed inside LEDs to serve as a natural vessel for in-situ QD integration. The effective light path can be extended by nano-porous structure to boost the overall efficiency due to the strong scattering effect. The reliability of quantum dots is - it is claimed- also improved greatly because of the high thermal conductivity of gallium nitride material.

Importantly, this technology claims to be able to integrate red, green, and blue pixels monolithically into a single chip to greatly reduce the complexity and cost of Micro-LED display manufacturing.

In this technique, nanopores in LEDs can be created by dipping the material in an acidic solution and applying a bias voltage, which drives electro-chemical etching of n-type GaN. By adjusting the etching voltage, one can change both the porosity and the size of the nanopores. Then the blue LED are bonded with exposed nanopores GaN to a current-driver panel and red/green QDs are selectively loaded to achieve Micro-LED full-color conversion.

Saphlux will present this on 30Nov-1Dec 2022 at TechBlick's microLED and QD event www.TechBlick.com/microLEDs

留言