Digital electrochemical multimaterial printing: bulk like, wide material choice, no curing

- khashayar Ghaffarzadeh

- Jun 14, 2023

- 2 min read

Syenta - an exciting start-up in Australia - is developing an electrochemical multi-material printing platform [digital printing machine + associated materials], addressing several critical shortcomings of traditional printing with particle-based ink/paste systems: bulk-like properties, wide material choice, no post treatment, and excellent z-direction [height] control.

Syenta will be exhibiting in Berlin on 17-18 OCT 2023 - join us and the global industry to RESHAPE Electronics, making it Additive, Sustainable, Flexible, 3D and Wearable - learn more https://www.techblick.com/electronicsreshaped

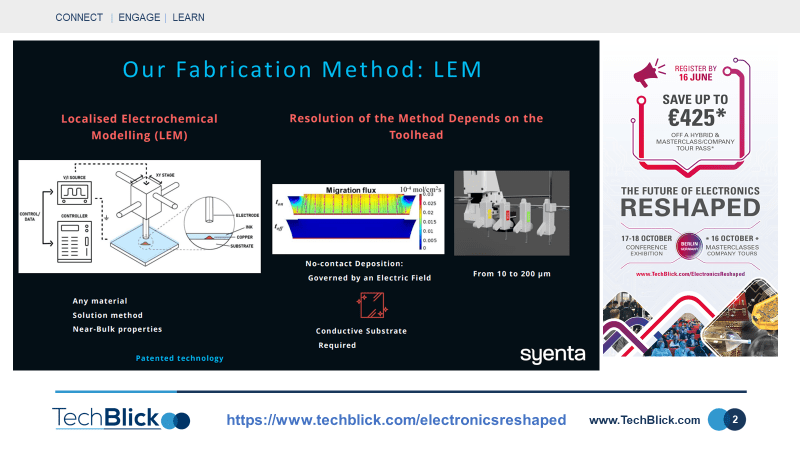

An example of their current printer [currently single nozzle with a 40x40 cm2 print area] is shown in slide [1]. The process is based on LEM or Local Electrochemical Modelling. Here, a local plating or electrodeposition takes place when an external controlled electrical potential is applied via the print head to a precursor solution. By control of the applied voltage as well as distances one can control many parameters including print speed, height, and linewidth.

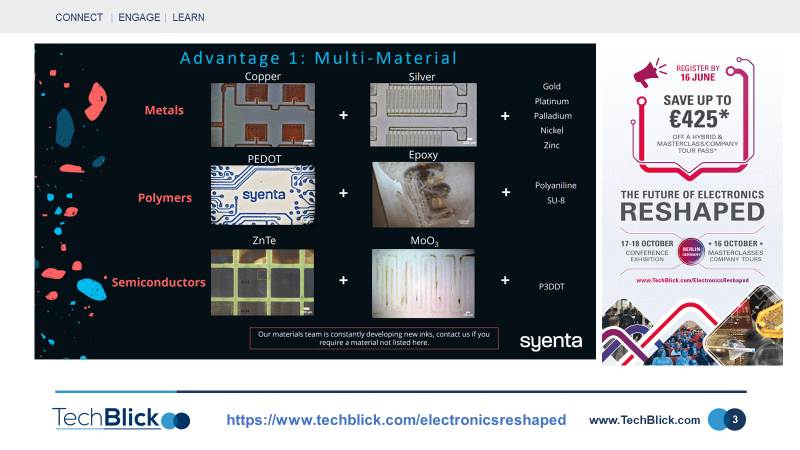

As you can in slide [2], this technique can be applied to a wide range of materials, covering conductive metals like copper as well as high viscosity polymers like epoxies and semiconducting materials like MoO3. In this way, it overcomes one of the limitations of particle-based ink systems which is the range of available materials.

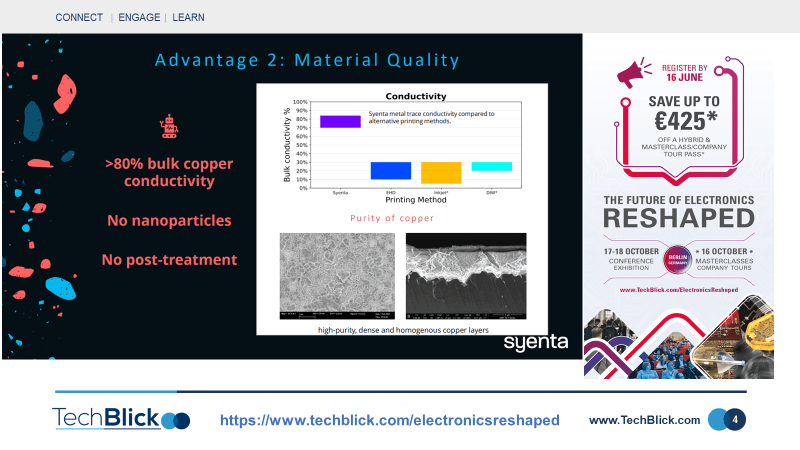

In slide [3] you can see the achieved conductivity. Given that it is a localized plating process, one achieves very bulk-like properties whereas epoxy based particle-based ink systems fall short especially when cured on low-temperature substrates.

Critically, given that this is a plating process, no post treatment like heat/IR/UV curing is needed. This is important because often curing limits print speed and costs in time, equipment, and production floor real estate.

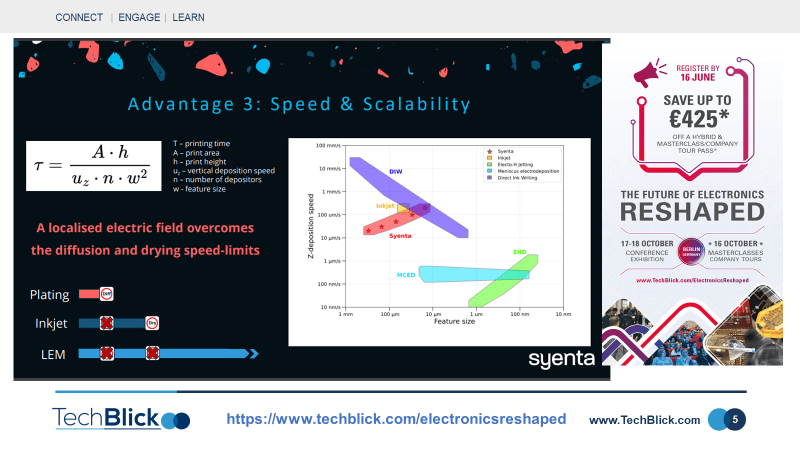

In slide [4], you can see the print speed, showing that the print process in the z-direction can be very high - reaching some 100 um per second. This means that - in the case of parallel print heads - high print speeds are possible since layers with sufficient thickness can be built up fast. This is still lower than some cases of DIW [Direct Ink Writing]. However, DIW has high speed when high volumes of inks/paste are deposited without accurate control of linewidth.

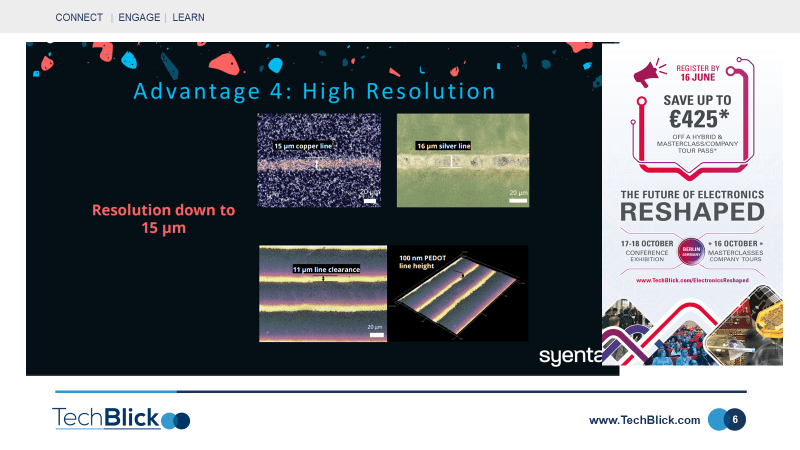

In slide [5], you can see also that this technique lends itself to very high resolution printing, achieving sub-20 um linewidths with different materials.

And finally in slide [6] you can see an example of a printed line with a height of 18um. This is important as most other digital printing techniques offer only thin layers with little ability to extend thickness.

This is thus an interesting technology. It is still in development. Of course - as with any emerging technology - there are innovation opportunities.

For example, the process works on conductive substrates. Thus enabling the process to deposit on non-conductive substrates [perhaps via lamination/de-lamination process] is of high interest. Or, a magic of ink based formulations is ability to adjust properties such as adhesion to different substrates. Currently, Syenta et al are expanding the box of tricks - at substrate and precursor level - to enable adhesion control on different substrates. Or significant engineering is required to enable multi-layer printing as print parameters[e.g., potential] depends on the conductivity of the underlying layer.

Nonetheless, this is a very promising and unique approach, solving a clear set of problems.

Comments