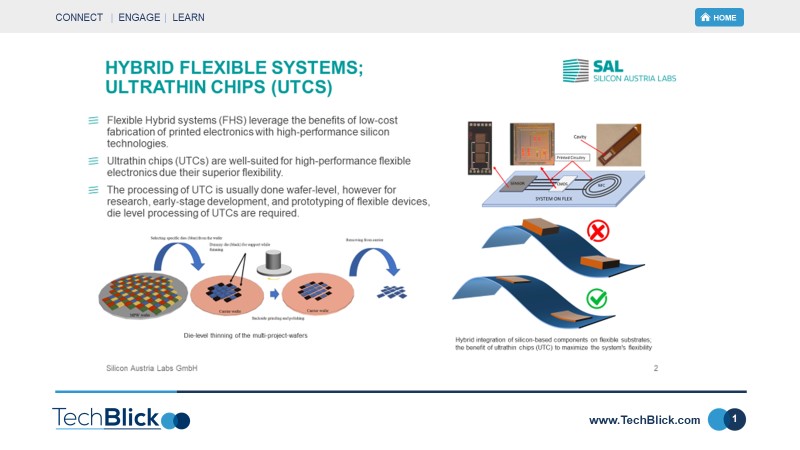

Hybrid flexible systems combine printed electronics with the high power computing of established silicon electronics. To keep systems truly flexible, ultra thin chips are utilized.

The slide below shows an example of preparing ultrachip dies from wafer singulation to creating thin dies. These dies are then placed upon flexible substrates with printed metallization and other printed components, creating hybrid flexible systems.

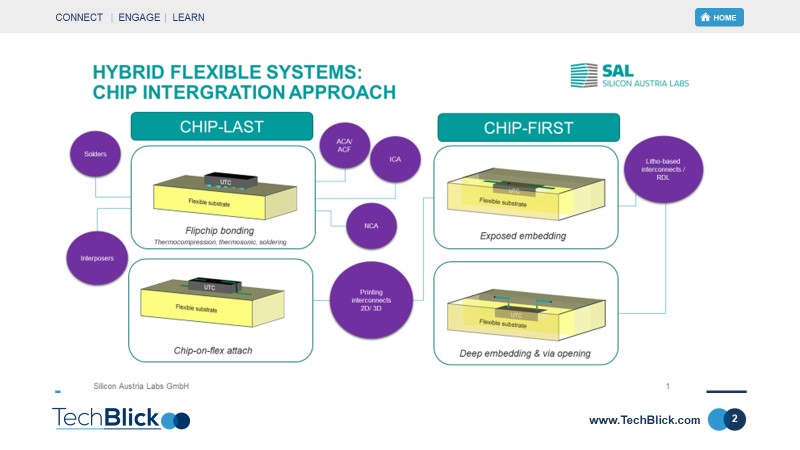

A key challenge here is bonding, in particular achieving ultra fine pitch bonding, so that a wider range of ICs - complex ICs with high I/Os - are compatible and so that electronic designers can choose from a familiar repertoire of components to create products

Slide 2 shows various chip integration approaches for flexible hybrid electronics. Broadly speaking, one can divide this into chip-first and chip-last approaches. In the chip first approach with flip chip bonding, traditional bonding techniques like solder, interposers, ACA/ACF, ICA, NCA, are utilized. In chip-last chip-on-flex techniques, printed interconnects are used. This is a hot area of development to enable complex next-gen flexible hybrid systems combining best-in-class chips with printed circuits

On 2 Dec, at TechBlick event on Printed Electronics Innovatipons, Ali Roshanghias from Silicon Austria GmbH will present the latest developments towards ultra fine pitch chip bonding. This is an open free-to-attend event bringing together 25 presenters over two parallel live tracks, 30+ live virtual exhibitors and 400+ attendees from around the world in a unique virtual environment.

You can see the full agenda and register FREE here

Comentarios