23 December 2024

Carbon Nanomembranes for Metal Anodes, Solid-State Battery Materials Testing, Sodium-Ion Batteries, and Roll-to-Roll Manufacturing Innovations

This issue of the TechBlick newsletter highlights battery technology, featuring insights from industry experts. Albert Schnieders from CNM Technologies discusses how Carbon Nanomembranes (CNMs) are enabling metal anode batteries by preventing dendrite growth and improving performance with standard separators. Dr. Christoffer Karlsson from rhd Instruments covers the improvements in solid-state battery materials testing through active pressure and temperature control. Rene Windiks from Materials Design explores atomic-scale modeling to optimize battery materials and enhance performance and safety. Marja Vilkman from VTT introduces the SOLiD EU project, focused on sustainable manufacturing and Roll-to-Roll (R2R) processes for solid-state batteries. Lastly, Shmuel De-Leon examines the growing sodium-ion battery market, its advantages and limitations, and the future of mass production. CNM Technologies | Enabling metal anode batteries by modifying the anode & separator interfaces with Carbon Nanomembranes rhd Instruments | Improving Solid State Battery Materials Testing through Active Pressure and Temperature Control Materials Design | Advancing Battery Materials Through Atomic Scale Modeling VTT | The development of R2R processes for manufacturing solid state batteries. The newly launched SOLID EU project Shmuel De-Leon | Sodium Ion (Na- Ion) Battery Market 2024. The Next Technology on Battery Mass Production Register by end of December and save 150 Euros! Use discount cod...

19 December 2024

Voltera: Printing Electroluminescent Ink on Paper and PET

As presented at the recent TechBlick’s Future of Electronics RESHAPED USA event held in Boston, our project, Multilayer Flexible Displays Using Electroluminescent Ink , validated the use of the Voltera NOVA material dispensing system to print a multilayer electroluminescent display on PET and paper using various Saralon inks. In this article, we explain how this project was achieved, covering the inks and substrates used, the steps we followed, as well as challenges and tips on printing flexible multilayer projects using the direct-ink-write technology. Contact: sales@voltera.io or +1 888-381-3332 ext: 1 Summary of Materials and Tools MATERIALS USED Saralon Saral Silver 700 Silver-Based Conductive Ink Saralon Saral Dielectric 600 Dielectric Ink Saralon Saral BluePhosphorl 800 Electroluminescent Ink Saralon Saral Conducting Polymer 700 Polymer Electrochromic Ink SUBSTRATES USED Polyethylene terephthalate (PET) Cardstock paper TOOLS AND ACCESSORIES Nordson EFD 7018424 dispensing tip Nordson EFD 7018333 dispensing tip Nordson EFD 7018482 chamfered tip Adafruit 12V EL wire/tape inverter Project Overview Purpose The purpose of this project was to demonstrate the multilayer capability of Voltera NOVA . We printed a blue light-emitting pattern - the Voltera logo - on two substrates: paper and PET separately, using electroluminescent ink. Design layout Electroluminescence operates by exciting a phosphor material with an electric field. An inverter is needed to convert the direct...

5 December 2024

Screen printed heaters, precision digital plasma deposition, 3D AME, Screen printed medical devices

In this edition, we explore exciting breakthroughs shaping the future of electronics. Fernando Zicarelli (E2IP Technologies) dives into the design and challenges of screen-printed heaters, comparing resistive and wire heaters while spotlighting transparent heater advancements. Ram Prasad Gandhiraman (Space Foundry) shares insights into plasma jet printing and its applications in aerospace, tackling issues like adhesion and material performance. Shavi Spinzi (Nano Dimension) showcases the move from 2D to 3D Additively Manufactured Electronics (AME), unlocking new possibilities for compact, high-performing devices. Finally, Marco Galiazzo (Applied Materials) highlights how advanced screen-printing is revolutionizing medical sensor production, offering a cost-effective way to create wearable health-monitoring devices. E2IP Technologies | Screen-printing Heating Devices: Limits and Challenges Space Foundry | Precision digital plasma deposition: deposit multilayer structure without curing Nano Dimension | Roadmap for 3D AME Designs Applied Materials | Advanced Screen-Printing: Manufacture a Medical Sensor by Screen-Printing The Future of Electronics RESHAPED USA is TechBlick's premier event, showcasing the latest innovations in electronics. Join us at UMass Boston on June 11-12, 2025 for an exciting exploration of emerging technologies. You can find more details on the event website here. EARLY BIRD rates are available until December 20, 2025 – secure your spot now! Registe...

29 November 2024

Photovoltaics: R2R Processing, CZTS Printing, Large Scale Perovskite, Laser Assisted Glass Encapsulation, Perovskite Stability, etc

In this newsletter, explore the advancements in solar technology, featuring InterPhases Solar's pioneering in-line roll-to-roll processes for flexible, thin-film devices, Crystalsol OÜ's innovations in CZTS photovoltaic technology, Taiwan Perovskite Solar's approach to large-scale perovskite production, Pixel Voltaic's laser-assisted glass encapsulation for perovskite photovoltaics, and University of Colorado Boulder's strategies to tackle degradation in perovskite solar panels. InterPhases Solar | Versatile in-line roll-to-roll process for flexible, thin film devices Crystalsol OÜ | Printed CZTS photovoltaic technology Taiwan Perovskite Solar | Large-scale perovskite production: materials, processes, and challenges Pixel Voltaic | Laser-assisted glass encapsulation for perovskite photovoltaics University of Colorado Boulder | Understanding & preventing degradation in perovskite solar panels The Future of Electronics RESHAPED USA is TechBlick's premier event, showcasing the latest innovations in electronics. Join us at UMass Boston on June 11-12, 2025 for an exciting exploration of emerging technologies. You can find more details on the event website here. EARLY BIRD rates are available until December 20, 2025 – secure your spot now! Register here TechBlick.com InterPhases Solar | Versatile in-line roll-to-roll process for flexible, thin film devices Shalini Menezes | 2024 Fabricating devices with non-vacuum roll-to-roll processes that intrinsically host nano-scale ...

19 December 2024

World's First System for Testing AR Contact Lenses

Authors: [1] Dr. Kedar Sathaye , Product Manager Light & Display at Konica Minolta Sensing Europe B.V. [2] Dr. Valentyn Volkov , co-founder of XPANCEO The market for image display devices is rapidly evolving, with innovations ranging from advanced screen technologies in smartphones and TVs to more sophisticated solutions like augmented reality (AR) glasses and virtual reality (VR) headsets, such as the Apple Vision Pro. The XR market alone is projected to reach an impressive $1,913.7 billion by 2032, with a growth rate of 39.2% from 2024 to 2032. There’s an increasing focus on making these devices more wearable and user-friendly. Achieving this goal, however, presents significant challenges due to the limitations of current technologies. Wearable devices, particularly in the AR and VR sectors, often face critical performance issues. For example, AR glasses and VR headsets frequently lack sufficient brightness, have limited battery life, and often end up being bulky due to the need for larger batteries. These issues can lead to overheating and reduced field of view, decreasing the practicality of these devices for long-term use. This is driving the industry to innovate and develop new devices that overcome these challenges. However, this rapid development invites another problem: the lack of comprehensive test solutions to ensure that these new devices meet the required standards for quality, safety, and performance. In response to this gap, Konica Minolta and XPANCEO have p...

16 December 2024

Design Tool Chain for Printed Electronics, Additive PCBs, Smart Surfaces with Printed Sensors, Scaling Up, Highly Conductive MXene

In this issue, we dive into technologies shaping the future of printed electronics and additive electronics, smart buildings, and additive manufacturing. From optimizing tool chains for 3D printed electro-mechanical structures to exploring low-volume manufacturing techniques for printed circuit boards (PCBs), this edition showcases advancements and practical applications. Featured companies include Siemens, Murata Manufacturing, Henkel, and BotFactory, each presenting innovations that are redefining industries. Learn how additive manufacturing and advanced materials are driving efficiency and sustainability in electronics production and smart infrastructure. Siemens | Optimizing the tool chain from Design through manufacturing for Printed Electronics Printed Electronics Ltd | Scaling up From Idea to Product With The PEL Open-Access Printable Electronics Production Facility Henkel - Laiier | Connecting surfaces of the smart building to the cloud with sensors enabled through PE Murata Manufacturing | Highly Conductive MXene for Electronics BotFactory | Exploring AM-PCBs for Low-Volume Manufacturing The Future of Electronics RESHAPED USA is TechBlick's premier event, showcasing the latest innovations in electronics. Join us at UMass Boston on June 11-12, 2025 for an exciting exploration of emerging technologies. You can find more details on the event website here. EARLY BIRD rates are available until December 20, 2025 – secure your spot now! Register here TechBlick.com S...

25 November 2024

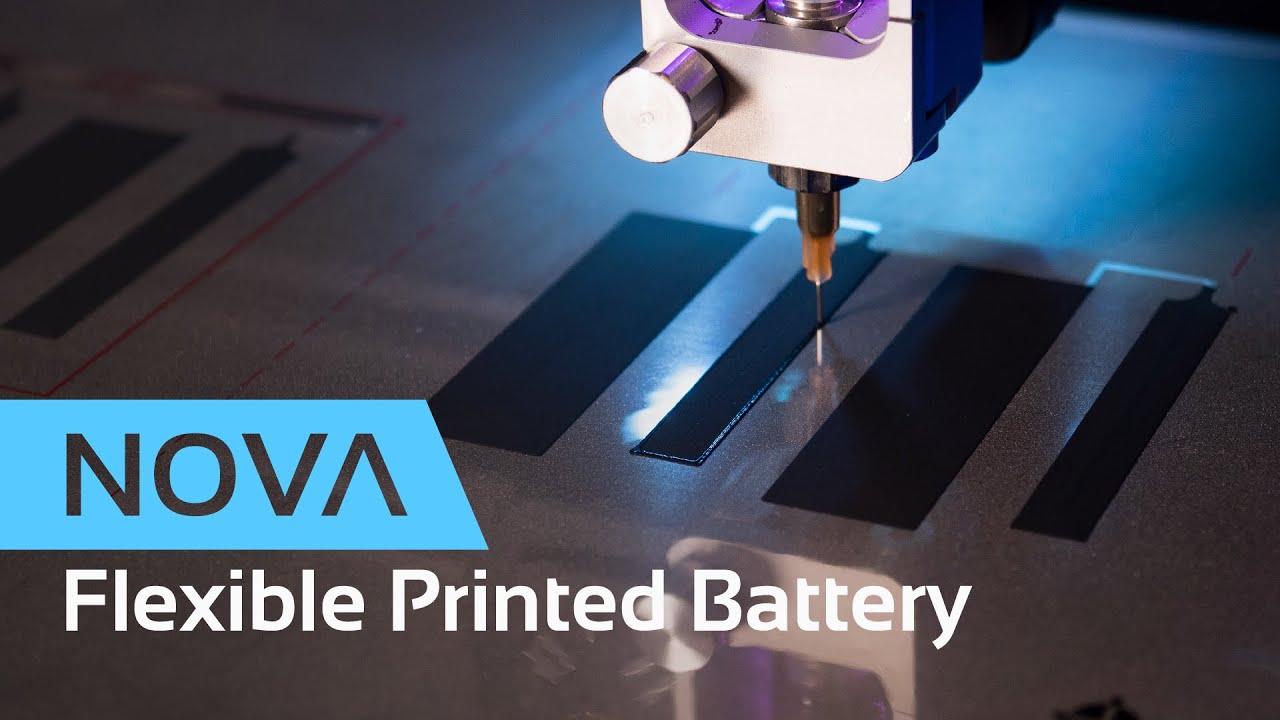

Voltera | Printing a Magnesium Zinc Battery with Saral Inks on PET

Author: Jesus Zozaya , CEO at Voltera | sales@voltera.io As presented at the TechBlick Berlin event in October, our project, a multilayer magnesium zinc battery, validated the compatibility of Saralon’s battery inks printed on a PET substrate.

Watch our Video: Printing a Flexible Magnesium Zinc Battery with Voltera NOVA MATERIALS USED Saral Silver 600A Battery Ink Saral Carbon 700A Carbon Based Conductive Ink Saral Zinc 700 Battery Ink Saral MnO2 800 Battery Ink Saral BatBarrier 600 Battery Ink Saral HotMeltGlue 800 Battery Ink Saral BatElectrolyte 700 Battery Ink SUBSTRATES USED Polyethylene terephthalate (PET) TOOLS AND ACCESSORIES Voltera NOVA materials dispensing system Nordson EFD 7018302 dispensing tip (330 µm ID) Nordson EFD 7018107 dispensing tip (840 µm ID) Nordson EFD 7018260 dispensing tip (410 µm ID) Nordson EFD 7018333 dispensing tip (250 µm ID) Heat press machine Dual asymmetric centrifugal mixer Project Overview Purpose The purpose of this project is to demonstrate how we fabricated a functional multilayer printed battery on a flexible PET substrate, validating the compatibility of PET with a variety of conductive and insulating inks. Image: Printed flexible battery-powering lights in a breadboard Design layout Typically, a printed battery consists of five layers: Current collector layer for the anode Anode layer Separator layer with electrolyte Current collector layer for the cathode Cathode layer Image: Schematic for typical printed batteries We se...